Woven mesh is made of high-quality stainless steel wire, nickel wire, copper wire, brass wire, Monel wire, Hastelloy wire and other metal wires using advanced weaving technology. There are many subcategories of weaving methods. Welded wire mesh is a mesh made by electric current welding with metal wire as raw material. The punching net is a net made of metal plate by stamping method. After processing, the area of the net is constant. Punched expanded mesh is commonly referred to as steel mesh, handle mesh, and expanded mesh. It is a mesh made of metal plates as raw materials by punching, shearing, and expanding.

What is sintered mesh?

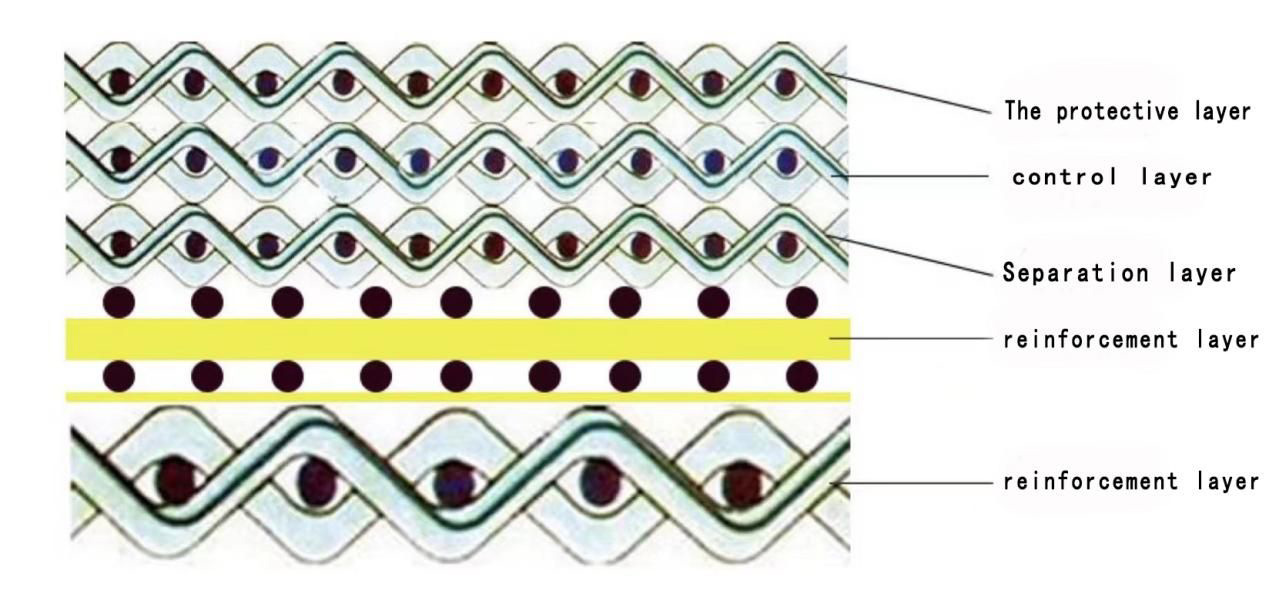

The sintered wire mesh is made by stacking multiple single-layer stainless steel wire braided meshes of the same type or different ones, after sintering, pressing, rolling and other processes, it is made by diffusion and solid solution after vacuum firing to 1100°C. New filter material with high mechanical strength and overall rigidity. The wire mesh of each layer has the disadvantages of low strength, poor rigidity, and unstable mesh shape, and can reasonably match and design the void size, permeability and strength characteristics of the material, so that it has excellent filtration accuracy and filtration impedance. , Mechanical strength, wear resistance, heat resistance and processability, the overall performance is obviously better than other types of filter materials such as sintered metal powder, ceramics, fiber, filter cloth, etc.

Sintered wire mesh is classified according to different levels and wire mesh structures, mainly including five-layer sintered wire mesh, multi-layer metal sintered wire mesh, punched plate sintered wire mesh, square hole sintered wire mesh and mat type sintered wire mesh.

Characteristics of sintered mesh

1. High strength and good rigidity: It has high mechanical strength and compressive strength, good processing, welding and assembly performance, and easy to use.

2. Uniform and stable precision: Uniform and consistent filtration performance can be achieved for all filtration precisions, and the mesh does not change during use.

3. Wide use environment: It can be used in the temperature environment of -200 ℃ ~ 600 ℃ and the filtration of acid and alkali environment.

4. Excellent cleaning performance: good countercurrent cleaning effect, can be used repeatedly, and has a long service life (can be cleaned by countercurrent water, filtrate, ultrasonic, melting, baking, etc.).

The main purpose

1. Used as dispersed cooling material in high temperature environment

2. Used for gas distribution, fluidized bed orifice plate material

3. Used for high-precision, high-reliability high-temperature filter materials

4. Used for high pressure backwash oil filter

Post time: Feb-21-2023